Solution Airborne performance is an attempt to give the performance of a basic single skin plastered brick wall with GenieClips walls added to. The improvement figure that is quoted is an idea of what can be expected over a basic starting point.

- Highest performance independent stud wall

- A vibration absorbing resilient corrugated steel bar

- Wall soundproofing at a level significantly above regulation requirements

- Online calculator will work out your exact requirements

- Consider the GenieClips that outperform resilient bars by ~7dB

| Solution: | Wall Depth Gain: | Solution Airborne Performance: | Typical Airborne Improvement: |

|---|---|---|---|

| Solution:50mm Stud. | Wall Depth Gain:108mm | Airborne Performance:59 dB | Airborne Improvement:22 dB |

| Solution:50mm Stud. + Tecsound 50 Upgrade | Wall Depth Gain:110mm | Airborne Performance:62 dB | Airborne Improvement:26 dB |

| Solution:75mm Stud. | Wall Depth Gain:133mm | Airborne Performance:61 dB | Airborne Improvement:26 dB |

| Solution:75mm Stud. + Tecsound 50 Upgrade | Wall Depth Gain:135mm | Airborne Performance:64 dB | Airborne Improvement:30 dB |

| Solution:100mm Stud. | Wall Depth Gain:158mm | Airborne Performance:63 dB | Airborne Improvement:28 dB |

| Solution:100mm Stud. + Tecsound 50 Upgrade | Wall Depth Gain:160mm | Airborne Performance:66 dB | Airborne Improvement:32 dB |

Solution Airborne performance is an attempt to give the performance of a basic single skin plastered brick wall with GenieClips walls added to. The improvement figure that is quoted is an idea of what can be expected over a basic starting point.

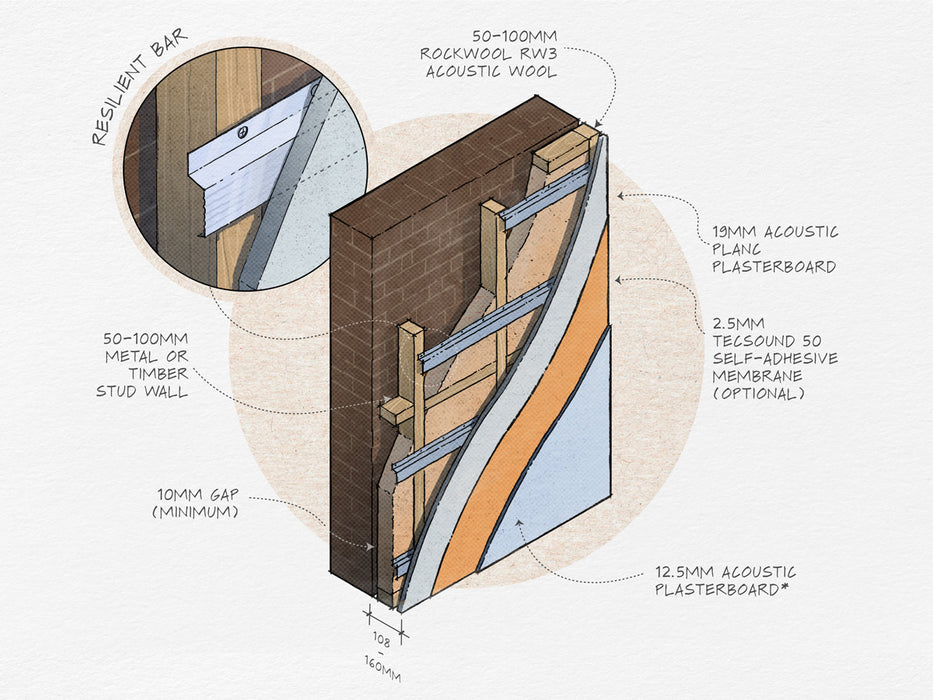

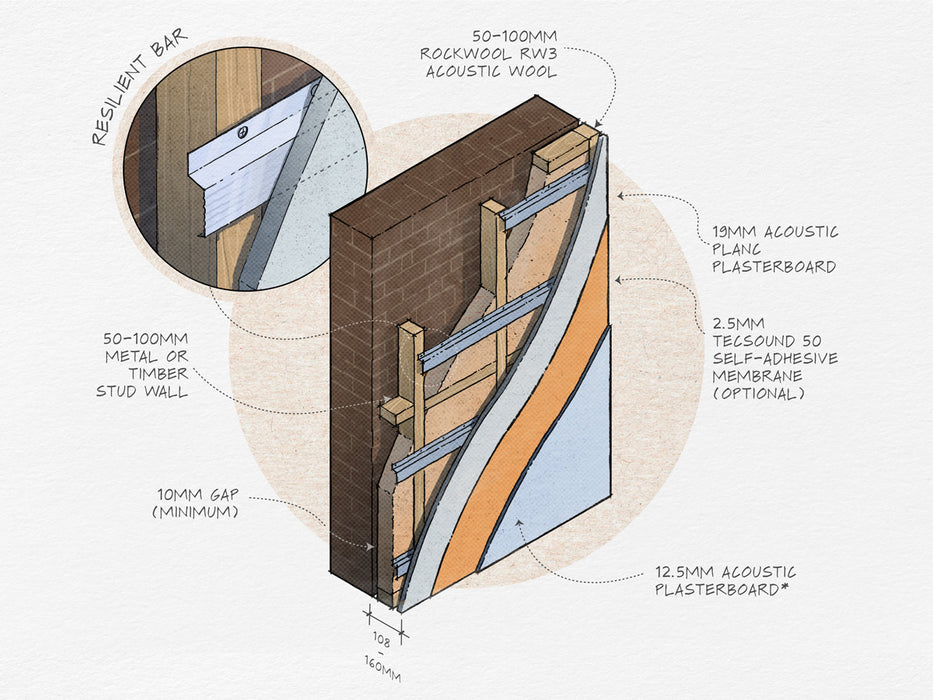

The independent stud wall will achieve great performance across the whole range of frequencies and is the best solution for low frequency sound. The wall must be independent of the existing structures, there must be a physical air gap between the new stud and the existing wall. It is the thickness of the solution which is integral to the performance of the solution.

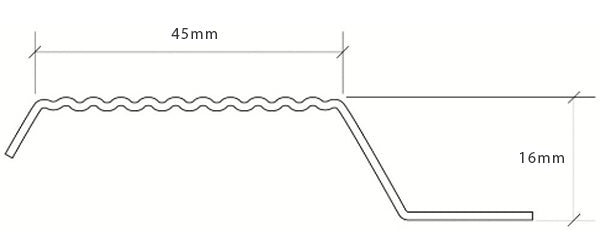

A vibration absorbing resilient corrugated steel bar used on timber studs and joists, for soundproofing walls and ceilings.

The most common application for resilient bars is for use in soundproofing a ceiling or a wall. One of the most important things to remember is that to ensure maximum sound insulation performance, screws fixing the plasterboard must not be in contact with the joists. When installing a dual layer of boards, all joints in the second layer must be staggered in relation to those of the first layer.

Where you are constrained by space issues the choice of a resilient bar may be your only practical choice when soundproofing a ceiling or wall. With this solution you will lose just over an inch (35mm) from your original wall or ceiling. The resilient bar, or sound breaker bar works by decoupling the new suspended stud wall or ceiling from the joists. The new wall or ceiling is in effect floating off the stud or joists via lightweight corrugated steel bars. The sound is absorbed as it travels through the corrugated flange of the resilient bar.

Resilient bars, as the name suggest act as the resilient layer that separates the mass of plasterboards from the rest of the surface that you are soundproofing. What is key to the success of any soundproofing work is that the weight you add should, where possible, be separated from the surface to be soundproofed by a resilient or springy layer.

In this case the light weight corrugated steel bars act as "springs" that allow the vibration and sound to be dissipated in a tiny movement. Resilient bars not only improve the impact characteristics but also the airborne characteristics of the surface you are soundproofing.

A rule of thumb would suggest that in a normal system where you are employing acoustic mineral wool, resilient bars and acoustic plasterboard, that the resilient bars will be doing about a third of the work from the airborne perspective and almost all the work form an impact perspective.

The removal of the original wall or ceiling sounds a little daunting but is in effect very easy to do. The only drawback is that it is a messy job. Resilience bars are attached to the stud or joists perpendicular to the run of the joists at 400mm centres. Acoustic mineral wool is then placed up in between the stud or joists. Finally a double layer of acoustic plasterboard is attached to the ceiling, the perimeter being sealed with acoustic mastic.

For more detailed installation instructions view the Independent Stud Wall Instructions.

Disclaimer: It is the responsibility of the installer/builder, not Soundstop.co.uk, to ensure all building and fire regulations are met, and that the construction itself is appropriate for the building and situation. Soundstop.co.uk can advise and give instruction on installation but hold no liability for the application itself.

Upgrade your soundproofing solution with the Tecsound acoustic membrane, which delivers an impressive performance boost. It is extremely flexible and improves both airborne and impact passage of sound.

It is a high density, polymer based synthetic soundproofing membrane providing excellent acoustic insulation in different construction elements. It is very flexible and very easy to use, an therefore has numerous applications, whilst also being self extinguishing and fire resistant.

The performance of the Tecsound Membranes is truly impressive. In fact, it's performance is equivalent to lead of the same surface weight. The Tecsound 50 in a single layer boasts an Rw figure of over 25dB and due its chemical make up it has exceptional damping qualities.

It is these qualities that are normally absent from rigid plasterboard type constructions. This resilience means that it compares very favourably to the likes of green glue, as it not only provides great resilience but it also provides high mass. The membrane has reinforcing scrim on one side and when applying the panels it should be facing you.

For those looking to reduce sound penetration to the maximum, an independent stud wall is the best choice and a good result can be achieved with resilient bars, however, for maximum performance the Genie clip system is the premium choice.

The GenieClip is a very high performance solution that provides the best single component we know when soundproofing a wall. The clip itself outperforms a resilient bar by around 6-7 dB, an impressive amount.

When soundproofing a wall it is necessary to improve three basic components.

1. The mass of the wall - Light weight walls do not soundproof as well as heavier walls. All the solutions we offer aim to increase the mass of the wall. This is generally achieved by adding acoustic plasterboard.

2. The resilience and acoustic separation of the wall - When designing the ideal acoustic wall you would, if space permits, create a new wall in front of the existing wall. The bigger the gap between the two walls the better the result, particularly for low frequency sounds. In action, this wall should have in built springiness which will mean it performs above and beyond a normal stud wall. This springiness, or resilience, can be achieved with Genie Clips or resilient bars. The performance of the mass on that wall is enhanced by around 40% when mounted using one of these solutions.

3. The sound "absorbency" of the wall -By adding different materials the sounds energy gets trapped more easily within the wall- The most cost effective method is the use of acoustic mineral wool.

However where noise is extreme from next door we have to add further elements.

1. Depth of soundproofing - The deeper your soundproofing barrier the better it performs. Hence 100mm walls are better than 50mm.

2. Separation - The deeper the soundproofing solution the more effective. However a physically separate wall ( even if separated by just 10mm from the original wall provides a significant uplift in performance. This stops the vibrations of the sound energy from reaching your side of the wall.

3. Acoustic Barrier -By adding different materials the sounds energy gets trapped more easily within the wall- For the absolute maximum protection an acoustic membrane can be incorporated into the mix.

You will notice two figures quoted. The total performance, which is normally quoted on most sites, refers to the performance of an average wall with soundproofing materials added. The other value is the improvement, or performance uplift, over the existing wall. Be very aware of sites that claim that the product they sell will improve performance by 40 dB. We know that this is not physically possible and that the figure quoted refers to a total performance figure including the existing wall being soundproofed.

When trying to understand the performance of an acoustic treatment look at the Db performance uplift. In broad terms every 10dB of performance uplift corresponds to roughly a 50% improvement in the performance of the wall. So 20dB would indicate a 75% Improvement over and above the original wall.

If you are thinking of refitting electrical sockets back into the wall. you might be advised to line your electrical boxes with our acoustic putty.

Remember, a 1% hole in your soundproofing surface can reduce performance of your soundproofing by up to 10%. Lining your plug sockets will go some way to reducing this leakage.

We are frequently asked whether it is necessary to run wall soundproofing around the chimney breast on a party wall?

While there is no definitive answer on this acoustic question, we are of the opinion that sound proofing the alcoves either side is usually sufficient. This is because chimneys are typically constructed to be fire and smoke proof and are at least of double brick construction, whereas the walls either side, the alcoves, may be poorly constructed and of single brick.

Of course there are exceptions, but in the majority of cases you can reduce your labour and time considerably by just sticking the acoustic panels in the alcoves.

Due to the acoustic nature of stud walls and timber framed walls we would recommend a different set of treatments when upgrading these walls as described in solution 5, stud wall soundproofing. Example results based on typical party wall construction of 100mm brick wall (38-43dB).

For those customers wanting to incorporate the highest performance materials into their soundproofing projects we introduce The GenieClip solution. The GenieClip is a very high performance solution that provides the best single component we know of when soundproofing a wall. The clip itself outperforms a resilient bar by around 7 dB, an impressive amount.

The GenieClip is screwed direct to stud work in the same manner that a resilient bar would be. Into the GenieClips, the furring strips are then clipped. To these furring strips plasterboard is then screwed. The GenieClip system is a superior alternative to the conventional resilient bar system. It produces better performance and is far less prone to fitting error. In fact its virtually impossible to fit incorrectly.

The GenieClip is a moulded rubber and steel isolation clip used to to control the passage of noise. The integral springing mechanism provides much more dampening than the corrugations of a resilient bar system. In fact, performance numbers are superior even with a single layer of plasterboard potentially saving on materials cost and labour.

It significantly improves low frequency sound control performance and this is often the hardest frequency to improve. Of all the resilient solutions that fix direct to joist it offers the best performance.

The gap between the door and the floor is often the biggest breach in a room's soundproofing but we have a range of solutions that can help.

Electric plug sockets are often one of the most overlooked weaknesses when a room is soundproofed but can reduce the performance by as much as 10%.