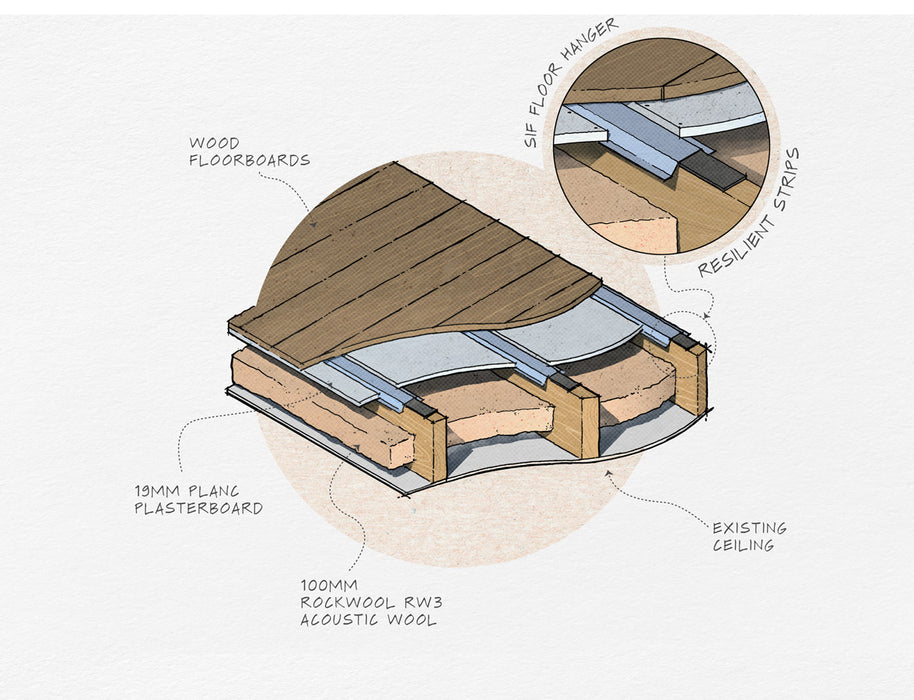

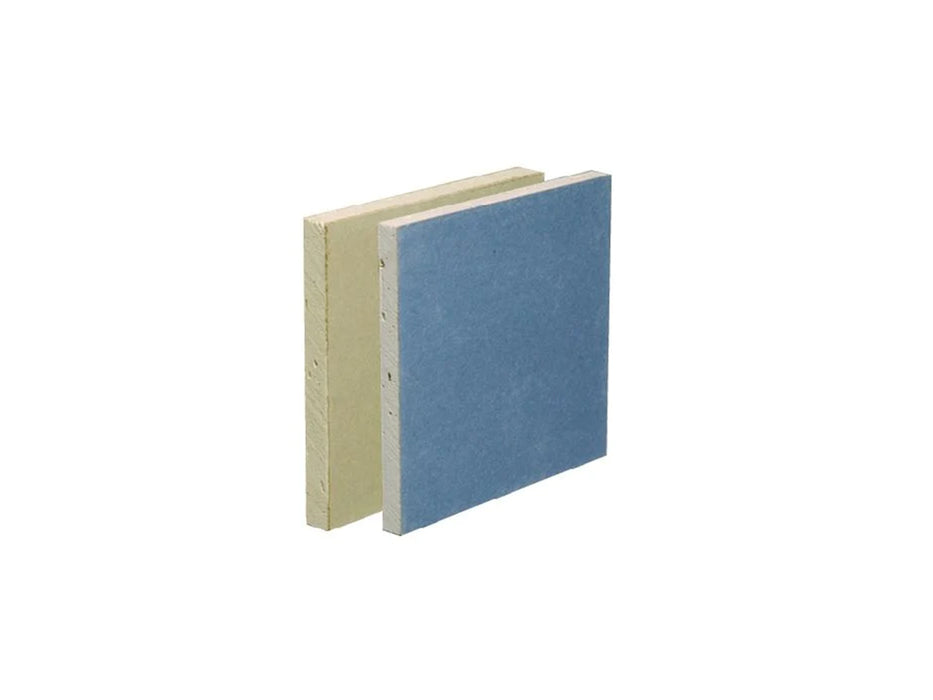

The new floor effectively sits upon a cushioned hanger that houses 19mm plasterboard.

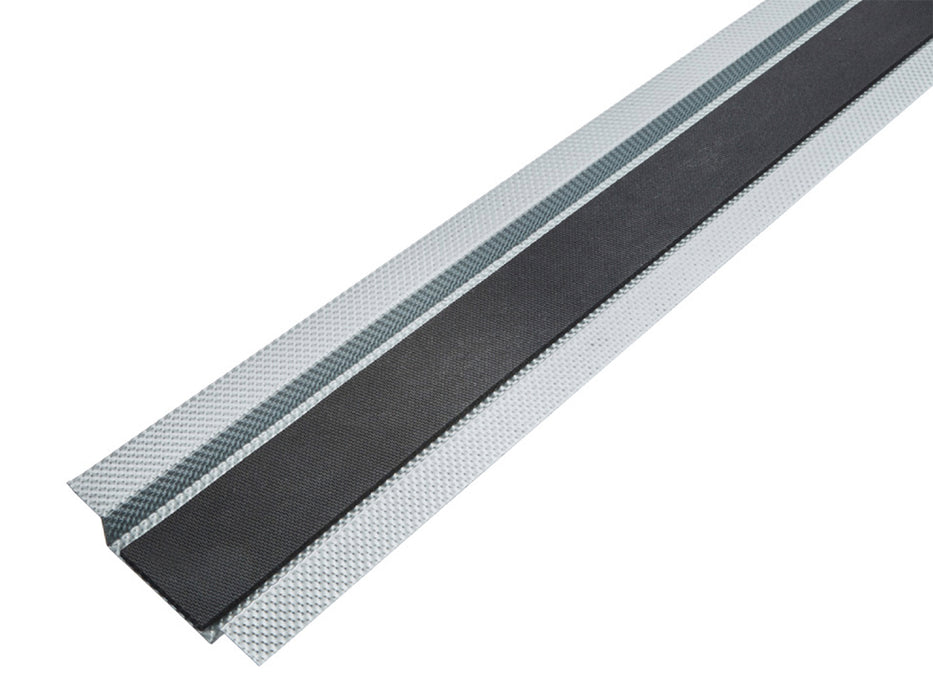

The new floor is screwed into the flanges of the hanger rather than back into the joist. The system creates a floating floor and allows the customer to retain original floorboards.

The addition of the 19mm plasterboard acts like an additional ceiling below your floor. Where possible gaps should ideally be sealed between the floor boards using acoustic mastic. The effect of this shouldn't be underestimated and can often be like closing a door that has been left ajar.

The floor will now have several layers of protection; Acoustic mineral wool, 19mm plasterboard planc, and sealed floor boards.

For more detailed installation instructions view the SIF Floor Instructions.

For customers looking to insulate noisy pipes please see our acoustic pipe wrap.

Disclaimer: It is the responsibility of the installer/builder, not Soundstop.co.uk, to ensure all building and fire regulations are met, and that the construction itself is appropriate for the building and situation. Soundstop.co.uk can advise and give instruction on installation but hold no liability for the application itself.