The base case scenario for a single stud wall is apporoximately 31dB this assumes no mineral wool and 12.5mm wall plasterboard (Wall board) fixed direct to the stud.

- Stud wall Soundproofing in a slim and effective way

- A very DIY-able upgrade

- Online calculator will work out your exact requirements

- Soundproofing Kit delivered direct to your door

| Solution: | Wall Depth Gain: | Solution Airborne Performance: | Typical Airborne Improvement: |

|---|---|---|---|

| Solution:50mm Stud. | Wall Depth Gain:35mm | Airborne Performance:44 dB | Airborne Improvement:13 dB |

| Solution:50mm Stud. + SBx Upgrade | Wall Depth Gain:26mm | Airborne Performance:50 dB | Airborne Improvement:19 dB |

| Solution:50mm Stud. + Tecsound 50 Upgrade | Wall Depth Gain:38mm | Airborne Performance:48 dB | Airborne Improvement:17 dB |

| Solution:75mm Stud. | Wall Depth Gain:35mm | Airborne Performance:47 dB | Airborne Improvement:16 dB |

| Solution:75mm Stud. + SBx Upgrade | Wall Depth Gain:26mm | Airborne Performance:53 dB | Airborne Improvement:22 dB |

| Solution:75mm Stud. + Tecsound 50 Upgrade | Wall Depth Gain:38mm | Airborne Performance:51 dB | Airborne Improvement:20 dB |

| Solution:100mm Stud. | Wall Depth Gain:35mm | Airborne Performance:50 dB | Airborne Improvement:19 dB |

| Solution:100mm Stud. + SBx Upgrade | Wall Depth Gain:26mm | Airborne Performance:56 dB | Airborne Improvement:25 dB |

| Solution:100mm Stud. + Tecsound 50 Upgrade | Wall Depth Gain:38mm | Airborne Performance:54 dB | Airborne Improvement:25 dB |

| Solution:SM20 | Wall Depth Gain:33mm | Airborne Performance:47 dB | Airborne Improvement:16 dB |

The base case scenario for a single stud wall is apporoximately 31dB this assumes no mineral wool and 12.5mm wall plasterboard (Wall board) fixed direct to the stud.

Typically, stud walls are built with physical separation of a room in mind. There is little consideration given to the acoustic performance of that wall. In many cases the wall will simply be constructed of 12.5mm plasterboard either side of a 50mm stud frame.

Situations where this may be a problem is when that separation is between two bedrooms or a bedroom and a bathroom. Post fitting of soundproofing should make it impossible to discern loud conversation.

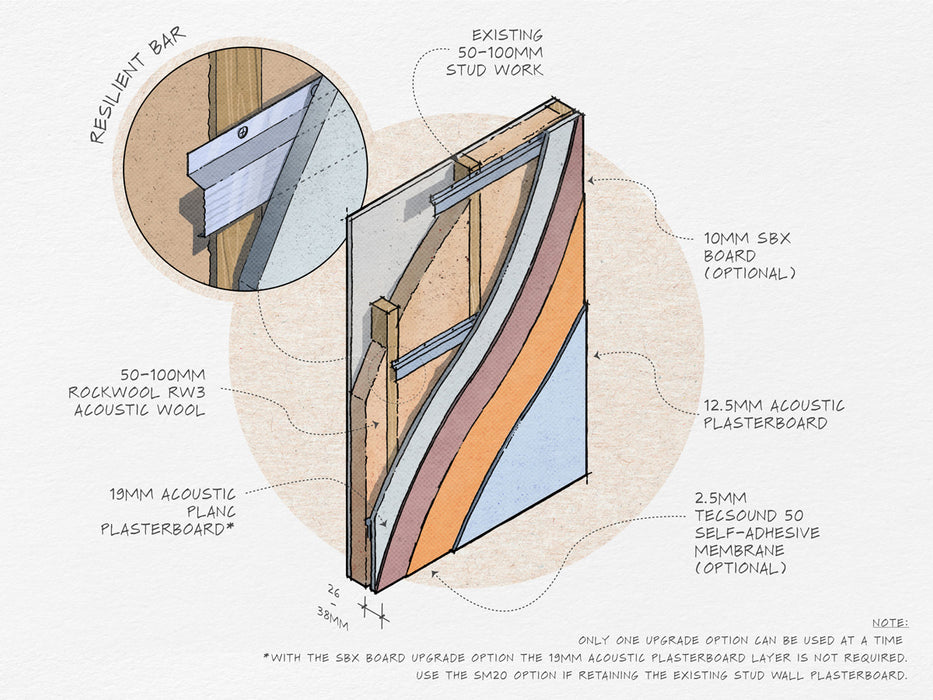

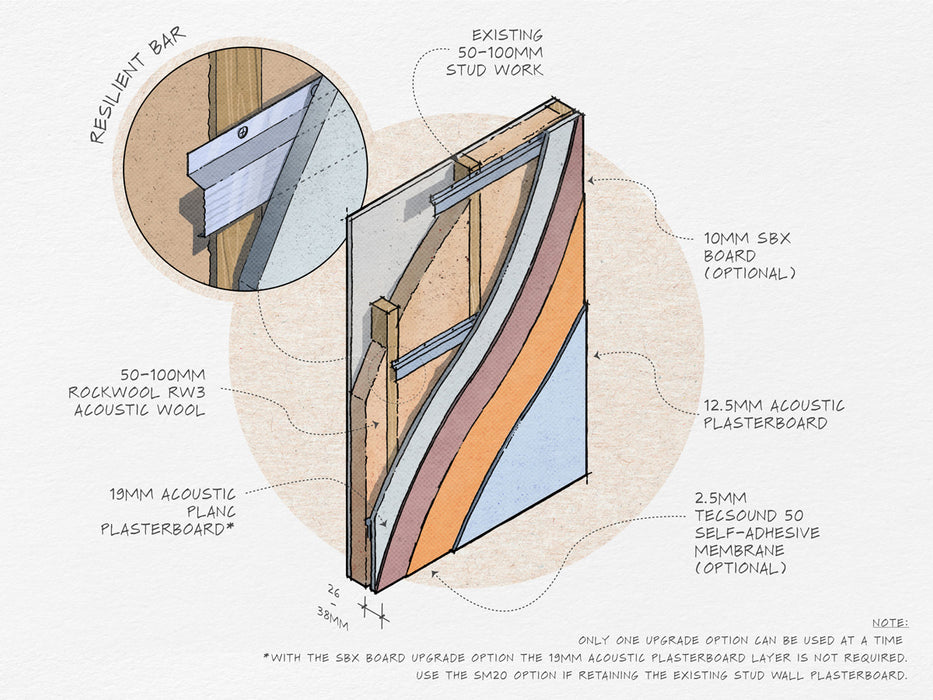

To upgrade and soundproof the stud wall you start by removing the original plasterboard from one of the faces of the wall. Once removed you infill with the appropriate thickness of acoustic mineral wool (choose 75mm wool for a 75mm wall).

You then install the 16mm deep resilient bars to the wall and finish the solution with two layers of 12.5mm acoustic plasterboard. The use of resilient bars creates a floating wall, which is key to for this soundproofing approach.

See the solution table above for the different size stud walls and different material options.

A vibration absorbing resilient corrugated steel bar used on timber studs and joists, for soundproofing walls and ceilings.

Where you are constrained by space issues the choice of a resilient bar may be your only practical choice when soundproofing a ceiling or wall. With this solution you will lose just over an inch (35mm) from your original wall or ceiling. The resilient bar, or sound breaker bar works by decoupling the new suspended stud wall or ceiling from the joists. The new wall or ceiling is in effect floating off the stud or joists via lightweight corrugated steel bars. The sound is absorbed as it travels through the corrugated flange of the resilient bar.

Resilient bars, as the name suggest act as the resilient layer that separates the mass of plasterboards from the rest of the surface that you are soundproofing. What is key to the success of any soundproofing work is that the weight you add should, where possible, be separated from the surface to be soundproofed by a resilient or springy layer.

For more detailed installation instructions view the Stud Wall Upgrade Instructions.

Disclaimer: It is the responsibility of the installer/builder, not Soundstop.co.uk, to ensure all building and fire regulations are met, and that the construction itself is appropriate for the building and situation. Soundstop.co.uk can advise and give instruction on installation but hold no liability for the application itself.

For a fast and effective method of upgrading a poorly soundproofed stud wall you can glue our SM20 panels direct to the face of the wall.

Either side can be chosen. Over the top of this can be added a double layer of acoustic plasterboard. If space is an issue then just choose one layer of acoustic plasterboard, and we recommend the 15mm acoustic plasterboard for this.

This will dramatically improve the performance of the stud wall. Select the SM20 Solution option to above to choose this approach.

The SM20 panel system is a high performance wall soundproofing solution aimed at those who want good acoustic performance. Unlike other solutions this dense recycled rubber is easy to fit and will provide a reliable soundproofing barrier.

Both of these approaches will drastically improve the acoustic performance of your stud wall. However, when superior performance is required we offer the addition of a Tecsound 50 upgrade, or for those who want even more soundproofing performance the SBx board, an award winning German designed soundproofing board.

A very high performance acoustic membrane, it is flexible and improves both impact and airborne passage of sound. It is a high density polymer based synthetic soundproofing membrane providing excellent acoustic insulation in different construction elements. The product is fire resistant and self extinguishing.

These boards are an excellent product designed to reduce the transmission of impact and airborne sound between two spaces. The product is our number one choice when trying to improve the soundproofing from noisy neighbours. SBx can be used for soundproofing walls, floors and ceilings whether constructed from timber, steel or solid substrate, in new builds, conversions, remedial and refurbishment projects.

Read more about the SBx Upgrade to find out exactly why we recommend it so highly.

Simply select these options above to add these upgrades to your soundproofing solution.

For those looking to reduce sound penetration to the maximum, the Genie clip system is the premium choice.

The GenieClip is a very high performance solution that provides the best single component we know when soundproofing a wall. The clip itself outperforms a resilient bar by around 6-7 dB, an impressive amount.

When soundproofing a wall it is necessary to improve three basic components.

1. The mass of the wall - This is normally achieved by adding acoustic plasterboard.

2. The resilience of the wall - This is the springiness of the wall. Without this, the addition of the mass will have very little impact. Here the use of the resilient bar is vital as it will greatly enhance the performance of the plasterboards. For even greater resilient performance Genie clips should be considered.

3. The sound "absorbency" of the wall - By adding different materials the sound energy gets absorbed more easily within the wall. The most cost effective method is the use of acoustic mineral wool.

A fourth component that can be added is a barrier component is a membrane that acts to block the sound but not by mass alone. For most of our systems we offer Tecsound 50 as a cost effective method of upgrading any soundproofing system.

The total performance which is normally quoted on most sites refers to the performance of an average wall with soundproofing materials added.

We also give an indication of performance uplift. Remember that every 10dB of performance uplift corresponds to roughly a 50% improvement in the performance of the wall. So 20dB would indicate a 75% Improvement over and above the original wall.

If you are thinking of refitting electrical sockets back into the wall. you might be advised to line your electrical boxes with our acoustic putty.

Remember, a 1% hole in your soundproofing surface can reduce performance of your soundproofing by up to 10%. Lining your plug sockets will go some way to reducing this leakage.

We are frequently asked whether it is necessary to run wall soundproofing around the chimney breast on a party wall?

While there is no definitive answer on this acoustic question, we are of the opinion that sound proofing the alcoves either side is usually sufficient. This is because chimneys are typically constructed to be fire and smoke proof and are at least of double brick construction, whereas the walls either side, the alcoves, may be poorly constructed and of single brick.

Of course there are exceptions, but in the majority of cases you can reduce your labour and time considerably by just sticking the acoustic panels in the alcoves.

Due to the acoustic nature of stud walls and timber framed walls we would recommend a different set of treatments when upgrading these walls as described in solution 5, stud wall soundproofing. Example results based on typical party wall construction of 100mm brick wall (38-43dB).

For those customers wanting to incorporate the highest performance materials into their soundproofing projects we introduce The GenieClip solution. The GenieClip is a very high performance solution that provides the best single component we know of when soundproofing a wall. The clip itself outperforms a resilient bar by around 7 dB, an impressive amount.

The gap between the door and the floor is often the biggest breach in a room's soundproofing but we have a range of solutions that can help.

Electric plug sockets are often one of the most overlooked weaknesses when a room is soundproofed but can reduce the performance by as much as 10%.