Joist Cap 2m

The Joist Cap is a cost-effective acoustic treatment designed for standard 50mm joists—delivering a Delta Lw reduction of 15–17dB, it’s a smart way to cut noise transfer without breaking the budget.

The Joist Cap is a cost-effective acoustic treatment designed for standard 50mm joists—delivering a Delta Lw reduction of 15–17dB, it’s a smart way to cut noise transfer without breaking the budget.

The GenieClip RST Soundproof System is a cutting-edge solution for effective noise isolation in walls and ceilings. Engineered to deliver market-le...

View full detailsThe SM20 Rubber Wall Panels are designed to provide high-performance soundproofing, particularly for airborne noise through party walls. Made from ...

View full detailsTecsound 100 Non-Adhesive Membrane is the highest-performing acoustic barrier in the Tecsound range, designed to reduce both airborne and impact no...

View full detailsThe Soundstop 6mm Acoustic Rubber Underlay is an effective, budget-friendly solution for reducing impact noise in various flooring applications. Ma...

View full detailsPhonestar SBx 15mm Boards are high-performance, German-engineered soundproofing panels designed for superior noise reduction across walls, floors, ...

View full detailsAbsorbalay 15 is a high-performance acoustic underlay that provides exceptional soundproofing for both airborne and impact noise. At only 15mm thic...

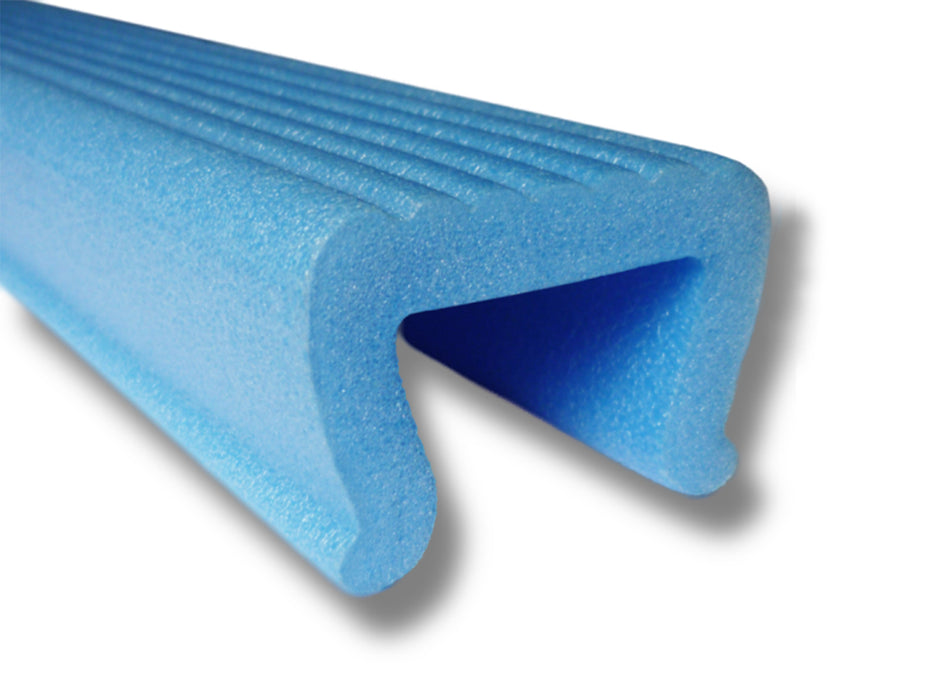

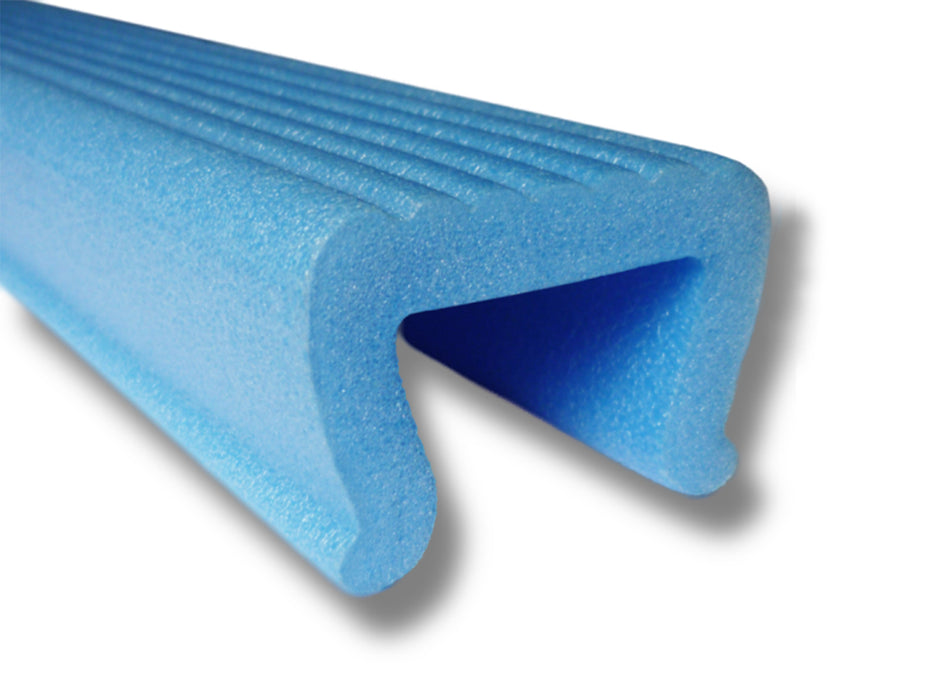

View full detailsThe Joist Cap 2m is an innovative and cost-effective acoustic solution designed to enhance soundproofing in floating floor systems. Engineered with high-quality, low-density foam, the Joist Cap provides superior sound attenuation while maintaining a stable and resilient flooring structure. Easy to install and Part E compliant, this product is ideal for both new builds and refurbishment projects, offering reliable performance for timber and masonry constructions.

A Joist Cap is an acoustic treatment product designed to fit tightly over standard 50mm timber joists, providing a resilient barrier between the structural floor and the floating floor. Manufactured from a low-density foam with advanced acoustic properties, Joist Caps are a practical and efficient solution for reducing noise transmission in floating floor installations. They are particularly effective at creating a stable, isolated flooring system that minimises sound transfer through the structure.

Joist Caps work by isolating the floating floor from the structural joists, preventing direct contact and reducing the transfer of sound energy. The castellated surface of the Joist Cap optimises sound attenuation by spreading the load across the floor and minimising the diaphragm effect. The resilient foam material absorbs and dampens vibrations, ensuring that airborne and impact noise are significantly reduced. The snug fit of the Joist Cap ensures stability, creating an acoustically isolated flooring system.

Joist Caps are highly effective at reducing both airborne and impact noise. When used as part of a direct-to-joist system, they deliver sound attenuation improvements of up to Delta Lw 15-17dB for timber floors. For concrete floors, when used upside down with resilient battens, they achieve Delta Lw improvements of up to 24dB. These performance levels exceed the requirements of Robust Details, making Joist Caps an excellent choice for superior soundproofing.

Joist Caps are versatile and suitable for a range of applications, including:

The installation process is straightforward and requires no specialised tools, making it ideal for both professionals and DIY enthusiasts.

This product, used upside down, can also provide the resilient layer required for customers to make up their own resilient battens.

If the product is used in this manner, on a concrete floor, impact improvements in the order of:

If the product is used in this manner, on a timber floor, improvements in the order of:

Robust Details only require an improvement of:

Please contact our team if you have any questions about this product

Here are the main details for this product:

Dimensions: 50mm x 2.0m

Thickness: 12mm

Pack Size: 1 Length

Weight: NA

Density: NA

Coverage: sqm

Fire Rating: NA

Visit our Fitting Instructions section for more detailed guidance specific to your application.

Please contact our team if you have any questions about this product.

If your looking for soundproofing for a particular situation or application, then the best place to start is with our soundproofing solutions that cover walls, floors, ceilings and reducing echo. Select the relevant application below to find out more.

Care should be taken to comply with all relevant Safety and Building Regulations.

The Joist Cap can be fitted from either above or below the joists and even before the joists are fitted.

The jaws of the caps are slightly tapered in to ensure a tight friction fit. Simply open the jaws and sit the cap over the joist ensuring the base is located tightly with the joist surface.

In all applications, our perimeter isolation strip must be used so the floating floor is fully isolated for the structural floor and walls.

Visit our Fitting Instructions section for more detailed instructions relating to your specific application.

Check out our Soundproofing Guides for more information, advice and tips on all aspects of soundproofing.