Resilient Bars are an innovative soundproofing solution designed to reduce both airborne and impact noise transmission through walls and ceilings. These lightweight, corrugated steel bars work by decoupling the new surface from the main structure, creating a "floating" system that minimises vibrations and noise transfer. Resilient Bars are ideal for residential, commercial, and industrial spaces where effective soundproofing is essential, and they are a popular choice for projects requiring compliance with Part E building regulations.

What Are Resilient Bars?

Resilient Bars are thin, corrugated steel channels engineered to absorb vibrations and reduce noise transmission in walls and ceilings. They are commonly used to decouple plasterboard from the underlying structure, creating a break in sound transmission pathways. Resilient Bars are particularly effective in situations where space constraints limit the use of other soundproofing methods, offering exceptional performance with minimal depth loss.

How Do Resilient Bars Work?

Resilient Bars function by creating a physical and acoustic separation between the plasterboard lining and the supporting structure. Here’s how they work:

- Decoupling:

-

Resilient Bars are fixed perpendicular to timber studs or joists, creating a suspended framework.

-

The corrugated design acts as a spring, isolating the plasterboard from the structural surface.

- Dampening Vibrations:

-

The corrugated steel absorbs sound-induced vibrations, reducing both airborne and impact noise.

-

This dampening effect significantly reduces the transfer of vibrations through walls and ceilings.

- Floating Effect:

- By decoupling the new surface, Resilient Bars create a "floating" system that minimises sound transmission pathways.

How Effective Are Resilient Bars at Stopping Nuisance Noise?

Resilient Bars are highly effective at reducing nuisance noise, especially when used as part of a complete soundproofing system. Their performance includes:

-

Airborne Noise:

-

Resilient Bars improve the insulation of airborne noise by approximately 30-50%, making them suitable for environments requiring privacy or quietness.

-

Impact Noise:

-

They are particularly effective against impact noise, such as footsteps, as the corrugated design absorbs vibrations before they travel through the structure.

-

Combined Performance:

-

When used with acoustic mineral wool and multiple layers of acoustic plasterboard, Resilient Bars can achieve noise reductions exceeding 300%.

Where Can Resilient Bars Be Used?

Resilient Bars are versatile and can be used in various settings:

- Ceilings:

-

Ideal for soundproofing ceilings, particularly in flats or multi-storey buildings where impact noise from above is a concern.

- Walls:

-

Suitable for both internal and partition walls in residential and commercial buildings.

- Compliance Projects:

-

Used to meet Part E building regulations for noise control in shared accommodations and new builds.

- Retrofits:

-

Effective for upgrading existing structures with minimal depth loss.

How to Install Resilient Bars

Installing Resilient Bars is a straightforward process that requires careful attention to detail to ensure maximum performance:

- Remove the Existing Surface:

-

Remove the original ceiling or wall covering to expose the timber joists or studs.

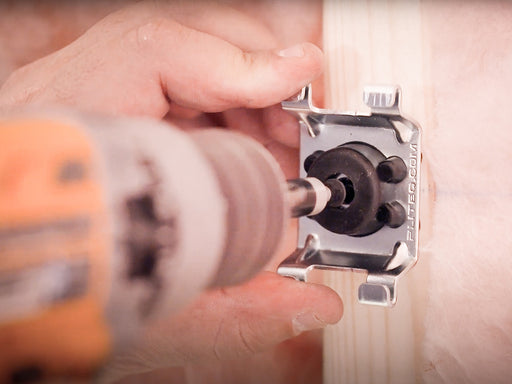

- Fix the Resilient Bars:

-

Attach Resilient Bars perpendicular to the joists or studs at 400-450mm centres using screws.

- Add Insulation:

-

Install acoustic mineral wool between the studs or joists for enhanced soundproofing.

- Attach Plasterboard:

-

Fix the first layer of plasterboard to the Resilient Bars using screws, ensuring they do not penetrate the joists.

-

Stagger the joints of the second layer of plasterboard to maximise acoustic performance.

- Seal the Perimeter:

-

Use acoustic mastic to seal the edges and prevent sound leakage.

What Are the Benefits of Using Resilient Bars?

- Space-Saving:

-

Minimal depth loss, making them ideal for projects with space constraints.

- Cost-Effective:

-

A budget-friendly solution compared to other soundproofing methods.

- Ease of Installation:

-

Simple to install with basic tools and suitable for DIY projects.

- Enhanced Acoustic Performance:

-

Significant reductions in both airborne and impact noise when combined with insulation and plasterboard.

- Regulation Compliance:

-

Meets Part E building regulations, ensuring high standards of noise control.

- Versatility:

-

Suitable for walls and ceilings in residential, commercial, and industrial applications.

- Durability:

-

Made from lightweight yet robust corrugated steel, ensuring long-lasting performance.

Resilient Bars offer an effective and practical solution for anyone looking to enhance soundproofing in their space. Whether used in ceilings, walls, or partitions, they provide outstanding noise reduction while maintaining a low-profile installation.

Looking for a complete resilient bar solution?

Wether your soundproofing a wall or ceiling, you will need plasterboards, wool insulation, screws, and other components to set up your resilient bars. Our handy solution calculators can work exactly number of each component you need to soundproof your wall or ceiling.

Wall Solutions:

Independent Stud Wall

Upgrading a Stud Wall

Ceiling Solutions:

Resilient Bar Ceiling

Independent Ceiling

Installation Instructions

Where the resilient bar is to be fixed to metal studs, fix bar at 600mm vertical centres. Fix the initial resilient bar 50mm down from the head of partition and the last bar 50mm from the floor. Screw the resilient bars to the studs using 13mm wafer-head screws. Screw the plasterboard to the resilient bar only, ensuring the screw does not touch the metal substrate. Bars are joined by butting together on the stud.

Instructions on fitting suspended resilient bar ceiling

1. Remove existing plasterboard ceiling. Sealing all door and windows to prevent dust escaping into the rest of the property.

2. Acoustic Mineral wool should be cut to size and friction fitted into the void

between the joists neatly so that no gaps are left.

3. Perpendicular to the run of the joists fit resilient bars at 400mm centres. The resilient bars should be fitted with the 32mm dry wall screws provided. Resilient bars should end close to walls. At the ends of the room resilient bar noggins need to be cut and fitted in the line of the joist where the joist runs near the wall. Where resilient bars need to be joined overlap them by 60mm.

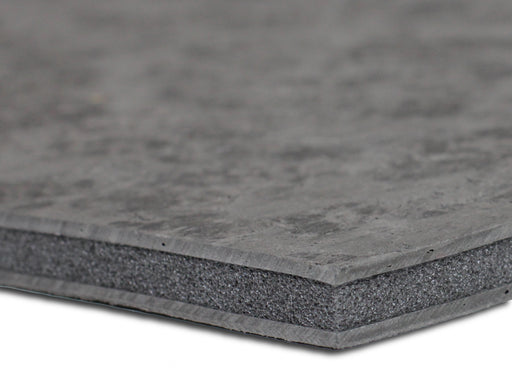

4. 19mm Planc boards are then screwed to the resilient bar flange with 32mm screws at 230mm centres. It is important to screw into the hanging flange of the resilient bar and NOT the joist. (This is critical to reduce impact sound from above) These should be fitted again leaving a small gap between them and the wall this can be filled with the sealant. Any gaps to be sealed with acoustic mastic provided.

5. If impact sound is a particular problem several wood noggins should be placed between the joists to firm up the flex in the floor 6- 8 should be sufficient. These ideally should be placed nearer the centre of the ceiling where flex is at its maximum.

6. 12.5mm soundbloc plasterboard is affixed next with 42mm screws screwing into the flange (mark line of resilient bar flange with chalk line or laser level, or pencil).

The joints of the soundbloc board should be staggered so that joints don’t coincide with 19mm planc boards.

7. The perimeter of the ceiling should sealed with the sealant provided. It is better to leave a small gap that can be sealed rather than butting the boards tight up against the walls. The sealant should applied at both levels of plasterboard.

8.Ceiling can be finished by taping and finishing with Easifil compound ( tape run along tapered join and Easifil applied to tapered depression and smoothed) or by plastering.

Visit our Fitting Instructions section for more detailed instructions relating to your specific application.

Check out our Soundproofing Guides for more information, advice and tips on all aspects of soundproofing.