Acoustic Downlighter Hoods are essential soundproofing and fire-protection covers designed to maintain the acoustic and fire integrity of ceilings with downlighter installations. These hoods provide an effective barrier against airborne and impact noise while restoring up to 60 minutes of fire resistance that can be compromised by downlighter openings. Available in a variety of sizes, Acoustic Downlighter Hoods are easy to retrofit and comply with British Standards for fire protection, making them ideal for residential and commercial spaces.

What are Acoustic Downlighter Hoods?

Acoustic Downlighter Hoods are foam-based, fire-retardant covers that fit over downlighters to seal and insulate the holes cut in ceilings for light fittings. They are designed to reduce the impact of noise transfer and maintain the fire rating of ceilings, ensuring that sound and fire resistance are not compromised. These hoods are available in various standard sizes and can be custom-ordered to fit different downlighter configurations.

How Do Acoustic Downlighter Hoods Work?

Acoustic Downlighter Hoods work by covering the gaps created by downlighter openings in ceilings. The hood acts as a barrier, sealing the cut-out area and preventing sound from easily passing through. The intumescent material in the hood expands in the event of a fire, creating an insulating layer that blocks heat and prevents flames from reaching the materials above the ceiling. This design helps to maintain the ceiling’s soundproofing properties and fire resistance, ensuring it performs similarly to a ceiling without downlighter openings.

What Type of Noise Do Acoustic Downlighter Hoods Stop?

Acoustic Downlighter Hoods effectively reduce both airborne noise—such as voices, music, and environmental sounds—and impact noise, including vibrations and structure-borne sounds. By adding mass and sound absorption above the light fittings, these hoods minimise noise leakage through downlighter cut-outs, helping to maintain the ceiling’s overall acoustic integrity.

Where Can Acoustic Downlighter Hoods Be Used?

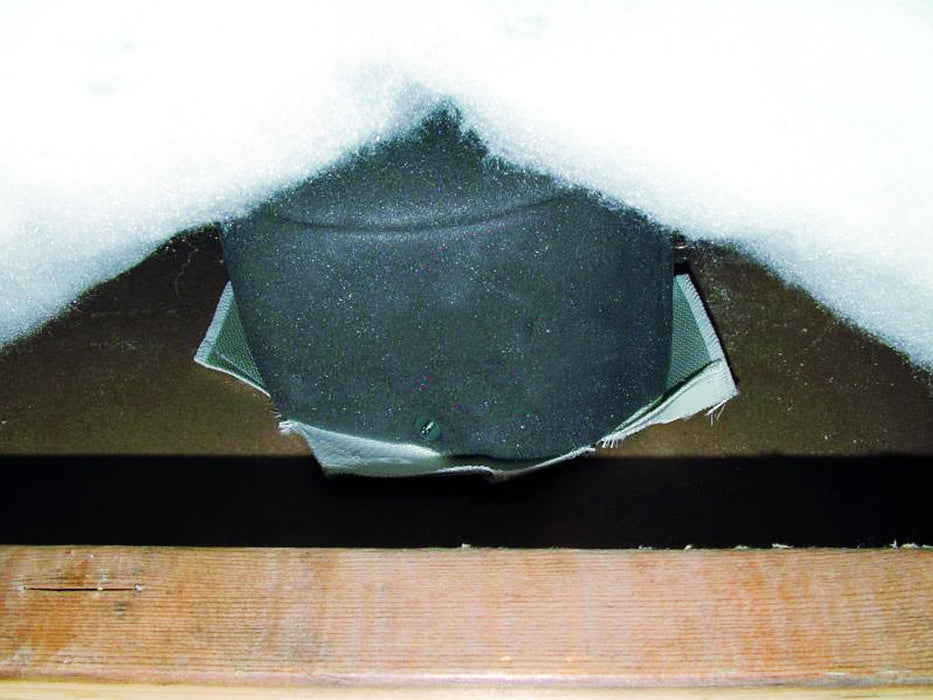

Acoustic Downlighter Hoods are versatile and can be used in suspended ceilings, roof areas, and ceilings with floorboards above. They are commonly installed in commercial buildings, residential properties, and other settings where downlighters are used, and where acoustic integrity and fire safety are essential. Additionally, these hoods are suitable for spaces that require high fire resistance, such as offices, retail stores, and public buildings.

How to Install Acoustic Downlighter Hoods

-

Feed the Cable: Lead the cable from the transformer through the downlight aperture in the ceiling.

-

Pierce an Entry Point: Create an opening in the top of the hood for the cable, ensuring it’s large enough for the cable size.

-

Compress and Insert: Compress the hood, pass it through the downlight opening in the ceiling, and allow it to expand fully inside.

-

Attach the Hood: Use the supplied pins to fasten the hood’s inner flanges securely to the plasterboard.

-

Insert the Light Fitting: Fit the downlighter into place, securing it over the hood’s inner flaps to seal the opening.

Installation is quick and straightforward, taking approximately five minutes and requiring minimal tools.

What Are the Benefits of Acoustic Downlighter Hoods?

-

Maintains Acoustic Integrity: Reduces noise transmission through ceiling cut-outs, preserving the room’s soundproofing.

-

Restores Fire Resistance: Provides up to 60 minutes of fire protection, ensuring compliance with fire safety standards.

-

Easy Retrofit: Simple to install from below or above the ceiling, making it a convenient solution for existing downlighter installations.

-

Multiple Sizes Available: Comes in various standard sizes to fit a range of downlighter models, with custom sizes available on request.

-

Prevents Overheating: Built-in ventilation to prevent overheating, ensuring safe use with light fittings.

-

Supports Robust Details: Meets UK building regulations, including Document B & E, and tested to European and British Standards.

Are the Acoustic Downlighter Hoods Fire Resistant?

Yes, Acoustic Downlighter Hoods are fire-resistant and provide up to 60 minutes of fire protection. Made with intumescent material, these hoods expand in high temperatures, creating an insulating barrier that prevents flames from passing through the downlighter opening. This fire-resistant feature restores the ceiling’s integrity, helping it meet the required British Standards for fire protection in commercial and residential buildings.