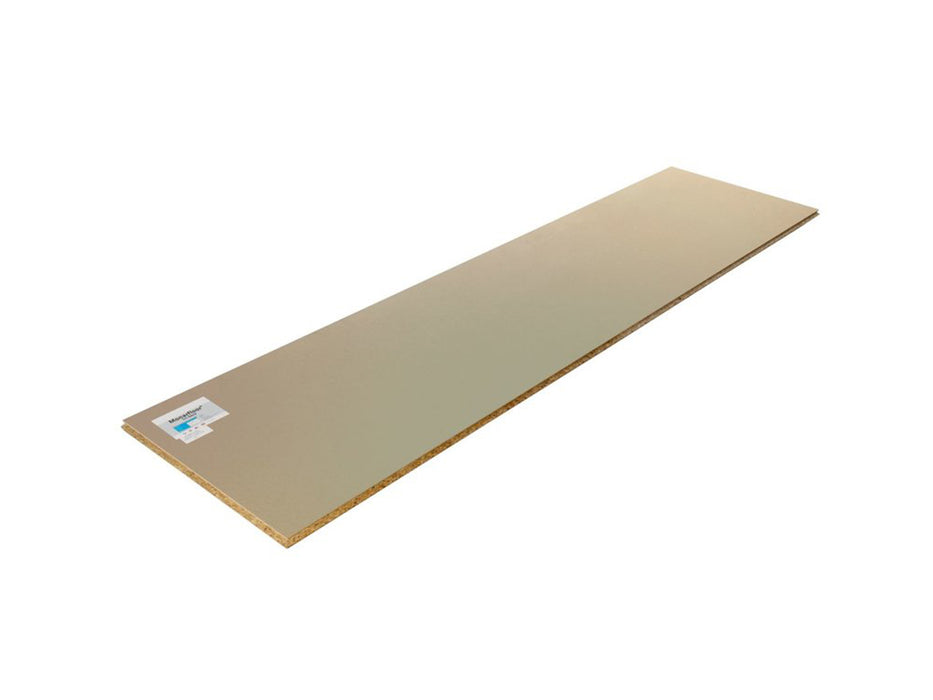

The Monarfloor Tri-Deck is a resilient overlay platform designed for direct-to-joist applications, making it an ideal solution for reducing sound transmission through timber floors. It is especially suited for scenarios where the existing timber floor needs to be removed but access to the ceiling below is restricted. With flame-retardant properties and compliance with Part E Building Regulations, this product offers superior performance for soundproofing applications.

What are Acoustic Floor Boards?

Acoustic floor boards are engineered flooring solutions designed to reduce the transmission of airborne and impact sound through floors. They incorporate layers of soundproofing materials, such as resilient foam, to disrupt sound waves and absorb vibrations. Acoustic floor boards like Monarfloor Tri-Deck help create quieter living spaces, particularly in multi-storey residential and commercial buildings.

How Do the Monarfloor Tri-Deck Acoustic Floor Boards Work?

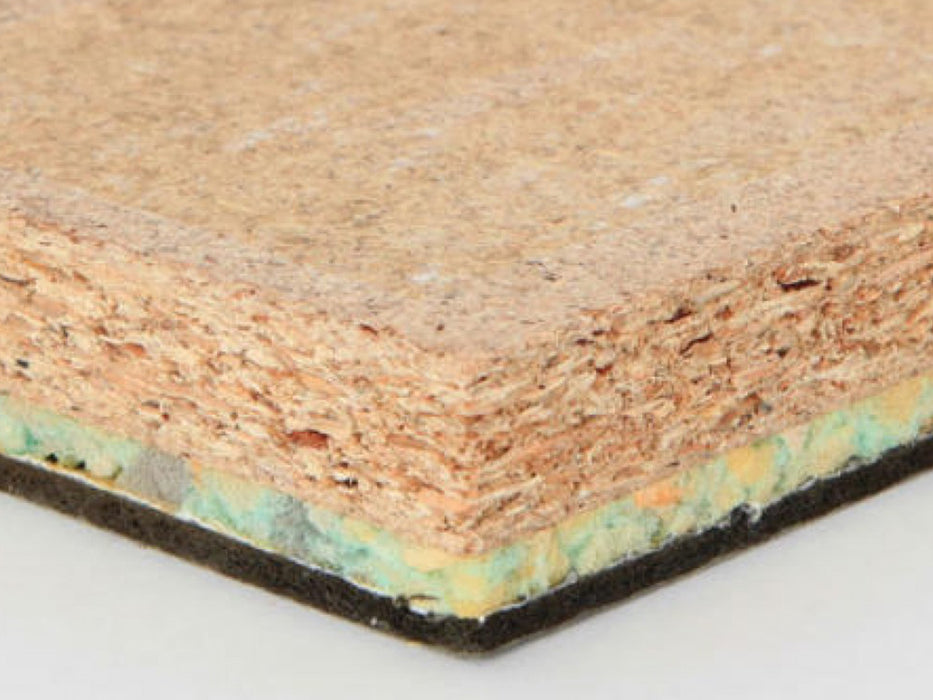

The Monarfloor Tri-Deck comprises:

-

5mm foam rubber layer: Absorbs impact vibrations and reduces resonance.

-

8mm Low Resonance Acoustic Chip (LRAC) foam layer: Minimises sound transmission and enhances acoustic stability.

-

22mm moisture-resistant chipboard layer: Provides structural integrity and supports various floor finishes.

This three-layer construction disrupts sound waves and prevents them from passing through the floor structure. The foam layers isolate vibrations, while the chipboard provides a stable platform for flooring.

How Effective Are the Monarfloor Tri-Deck Floor Boards at Stopping Nuisance Noise?

The Monarfloor Tri-Deck is highly effective at reducing both airborne and impact noise:

-

It eliminates the need for acoustic ceilings by directly addressing sound transmission through the floor.

-

The LRAC foam enhances impact noise reduction, providing a quieter environment even when dealing with footfall or furniture movement.

-

When combined with sufficient mass (such as lath and plaster ceilings), it can meet or exceed Part E Building Regulations for soundproofing.

Where Can the Monarfloor Tri-Deck Be Used?

The Monarfloor Tri-Deck is versatile and suitable for:

-

Residential properties: Reduces sound transmission between floors in homes and apartments.

-

Historic buildings: Ideal for scenarios where access to the ceiling below is restricted, such as rooms with ornate cornicing or coving.

-

New builds and refurbishments: Provides soundproofing in timber frame constructions and conversions.

-

Direct-to-joist applications: Minimises floor height build-up, making it ideal for areas with height constraints.

How to Install the Monarfloor Tri-Deck Boards?

- Prepare the Joists: Ensure joists are clean, level, and free from debris.

- Install Insulation: Place 45-60kg/m³ mineral wool (100mm thick) between the joists for enhanced soundproofing.

- Lay the Boards:

-

Position the boards directly onto the joists.

-

Use a broken bond pattern to enhance stability.

- Fix Securely: Screw or nail the boards to the joists as per the manufacturer’s instructions.

- Seal Gaps: Use acoustic sealant or flanking strips at the perimeter to create an airtight seal.

- Prepare for Finishing: Ensure the surface is smooth and ready for the chosen floor finish.

What Are the Benefits of Using the Monarfloor Tri-Deck Acoustic Boards?

-

Superior Soundproofing: Reduces airborne and impact noise effectively.

-

Direct-to-Joist Application: Eliminates the need for an acoustic ceiling and reduces floor height build-up.

-

Flame Retardant: Meets stringent fire safety standards.

-

Part E Compliant: Ensures compliance with Building Regulations for soundproofing.

-

Quick and Easy Installation: Simplifies the installation process, saving time and labour costs.

-

Durable Construction: Moisture-resistant chipboard provides a robust base for various floor finishes.

-

BBA Certified: Assured quality and performance.

How to Tile on Top of an Overlay System?

To tile over the Monarfloor Tri-Deck:

- Use Appropriate Adhesives: Choose adhesives and grouts designed for floating floors, as recommended by the Tile Association.

- Add a Tile Board Layer: Overlay the Tri-Deck with proprietary tile boards or plywood to stiffen the floor and improve water resistance.

- Select Suitable Tiles:

-

Use porcelain tiles for durability.

-

Avoid thick or heavy tiles like marble.

-

Limit tile size to 450mm x 450mm for better stability.

- Consult Manufacturers: Speak with adhesive manufacturers for specific recommendations based on their products.

We advise you follow the guidance issued by the Tile Association in dealing with floating floors.

By following these steps, you can ensure a stable and durable tiled surface over the Monarfloor Tri-Deck, suitable for residential and commercial applications.

Here are the main details for this product:

Dimensions: 2400mm x 600mm

Thickness: 35mm

Pack Size: 10 Board Minimum

Weight: 30.5kg per Board

Density: TBC

Coverage: 1.44 sqm

Fire Rating: Flame retardant

Visit our Fitting Instructions section for more detailed guidance specific to your application.

Please contact our team if you have any questions about this product.

Looking for a complete soundproofing solution?

If your looking for soundproofing for a particular situation or application, then the best place to start is with our soundproofing solutions that cover walls, floors, ceilings and reducing echo. Select the relevant application below to find out more.

Wall Solutions

Floor Solutions

Ceiling Solutions

Echo Solutions

Instructions for use

Monarfloor Tri-Deck should be laid directly onto the joists in a broken bond pattern with all joints glued and perimeters flanked.

Diagram Key:

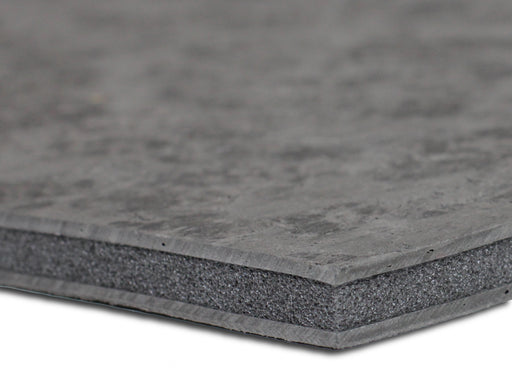

1. Acoustic Flanking Band – reduces impact vibration transmission via party and flanking walls and assists in reducing airborne sound paths

2. 100mm 45kg/m³ insulation

3. 22kg/m² double boarded ceiling on resilient bars perpendicular to joist direction

4. Monarfloor Tri-Deck system

Installation at a glance

- Flank all perimeter with Monarfloor Flanking Band

- Level the sub-floor to the required tolerance

- Lay Monarfloor Tri-Deck platform floor / floating floor system directly over the floor joists in a broken bond pattern with all joints supported and glued

- Install skirting and trim off excess Flanking Band

Tools & equipment required

- 1 litre of Monarfloor® Acoustics Adhesive for every 21.5m2 of deck (approx). Note: Adhesive should be applied in well ventilated rooms

- 1 linear metre of Monarfloor Flanking Band for every 1m2 of flooring

- Utility knife and straight edge

- Joinery hand/power tools

Check sub-floor is suitably prepared

- Ensure the surfaces are structurally sound, clean and dry

- All internal partitions should be installed and built of the joists

- Kitchens and bathrooms should also be built of the joists (see Monarfloor Generic Kitchen & Bathroom Detail Drawings)

- Ensure the correct mineral wool insulation has been packed tightly between the floor joists

- Support the ends of boards with noggins if required

Tiling on top of Monarfloor

We advise you follow the guidance issued by the Tile Association in dealing with floating floors, which is:

- Adhesives and grouts must be suitable for floating floors. There are various systems depending on the individual manufacturers detailing.

- Proprietary tile boards or ply, can be overlaid to provide additional water tightness, and or stiffen the floating floor. These must be bonded.

- Tiles should ideally be porcelain. We do not advise thick heavy tiles such as marble etc as they are more susceptible to fracture.

- Tile format must be kept as small as possible (600 x 600mm max). We would advise 450mm x 450mm.

You should also speak to the adhesive manufacturer that is being used as they all have specific detailing to their own products.

Care of materials

Materials must be kept in a dry storage area at all times.

Working Safely

- Working on any building site can be a hazardous activity. Only suitable persons having appropriate competence, training and physical fitness should be allowed onsite.

- Personal Protective Equipment (PPE) must be worn at all times.

Visit our Fitting Instructions section for more detailed instructions relating to your specific application.

Check out our Soundproofing Guides for more information, advice and tips on all aspects of soundproofing.