The GenieBoard 302 is a dry screed overlay board designed to make flooring faster, smarter, and quieter. It replaces traditional poured screed or layered board methods, delivering a high-performance, low-hassle solution that works straight out the box. Whether you're building new, refurbishing existing floors, or working under tight timelines, GenieBoard 302 combines installation speed, reliable soundproofing, and improved thermal insulation in one solid, user-friendly board. Ideal for both domestic and commercial use, it’s engineered to meet today’s performance expectations without the fuss.

What is a GenieBoard 302?

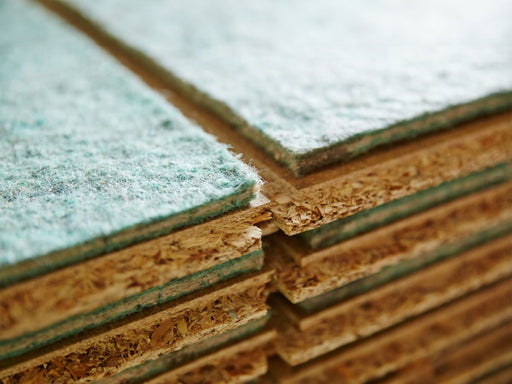

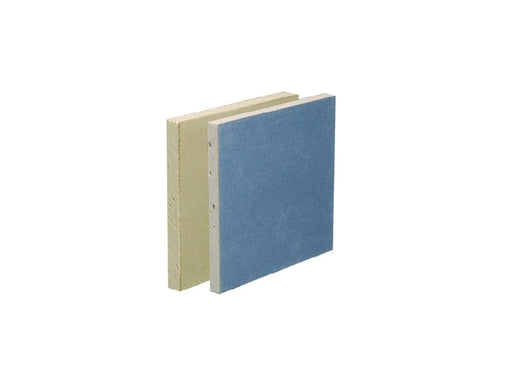

GenieBoard 302 is a universal dry flooring board, 25mm thick, designed as a smarter alternative to traditional wet screeds or stacked subfloor layers like plywood or cement board. It measures 500mm x 1500mm with a 50mm shiplap joint for tight, seamless fitting. Each board covers 0.75m² and weighs in at 29kg/m²—robust enough for serious foot traffic, yet easy enough to handle onsite. With flame-retardant properties and compatibility across floor types, it’s a reliable foundation for residential, commercial, or mixed-use developments.

How Do the GenieBoard 302 Work?

The magic lies in the simplicity. GenieBoard 302 uses a tongue-and-groove edge detail and shiplap joint system to create a tight interlocking fit. Fixed at 200mm centres using 22mm screws or staples, the system eliminates the inconsistencies and cure times of wet screed. Once down, it delivers a flat, dense, acoustically dampened surface ready for final flooring—no cracks, no waiting, no mess. This efficient dry system also avoids the moisture risks associated with traditional methods, making it ideal for moisture-sensitive environments.

What Type of Noise Do the GenieBoard 302 Stop?

GenieBoard 302 delivers proven acoustic performance. On a bare 140mm concrete slab with no ceiling, it achieves Rw (+Ctr) 65 (-10)dB for airborne sound, and Ln,w 50dB with a ΔLn,w improvement of 29dB for impact sound. That’s a 5dB improvement over typical airborne sound requirements and a 12dB lift over Part E impact sound benchmarks. Translation: it stops heavy footfall, voices, and dropped items from travelling between floors, improving peace and privacy in multi-level buildings.

Where Can the GenieBoard 302 Be Used?

This board’s versatility is its strength. GenieBoard 302 is suitable for lightweight timber frames and heavyweight masonry builds alike. It works over GenieMat products or as a standalone solution under any common flooring finish—tiles, wood, carpet, vinyl, laminate. It shines in projects where poured screed isn't an option, like loft conversions or refurbishments with restricted ceiling access. Whether it's a new build apartment block or a retrofitted office, GenieBoard 302 adapts to the job.

How to Install the GenieBoard 302

Installation is clean and straightforward. Position the boards with the shiplap joint aligned, fix at 200mm intervals using 22mm screws or staples, and you’re done. There’s no mixing, no drying, and no waiting around. The boards can be trimmed to size with standard tools and laid quickly in sequence, making it ideal for installers who value speed and precision. Once installed, it’s ready to receive floor finishes almost immediately.

What Are the Benefits of the GenieBoard 302?

-

Faster installation than wet screed—no drying, no delays

-

No drying time required—just fit and finish

-

Excellent sound and thermal performance—meets and exceeds regs

-

Lightweight and easy to handle—no lifting gear needed

-

Flame retardant (A2fl-s1 rated)—complies with fire safety standards

-

Universal compatibility—works with all GenieMat products and flooring types

-

Strong load capacity—up to 3kN on a 7850mm² area, great for high-traffic areas

GenieBoard 302 is the get-it-done solution for acoustic and thermal flooring that doesn’t hold up your build. It’s performance-first, hassle-free, and built to keep things moving.

How to Install the GenieBoard 302

Installing GenieBoard 302 is straightforward and doesn’t require specialist tools or wet trades. Follow these steps:

Preparation

Start by checking that the subfloor is solid, dry, clean, and free from dust or debris. This ensures a stable base and long-term performance.

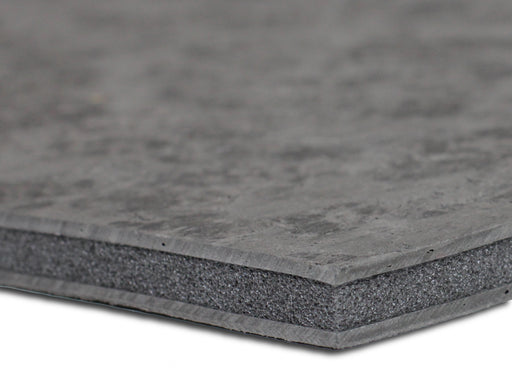

If using GenieMat underlayments, lay these out evenly across the subfloor first, following the manufacturer’s instructions. This step helps improve overall acoustic and thermal results.

Planning

Dry-lay a few boards to plan your layout and reduce waste. Stagger joints in a brickwork-style pattern for greater structural strength and a smoother final finish.

Always leave a 5–10mm expansion gap around all perimeter walls, columns, door frames, and pipework. This prevents buckling or creaking as the building breathes.

Cutting

Measure carefully and use a circular saw, jigsaw, or fine-toothed handsaw to trim boards to size. Cut edges should face perimeter walls or be tightly butted against the next board.

Wear a dust mask and cut in a well-ventilated space.

Laying the Boards

Start in a straight corner of the room, placing the first board with its tongue facing outwards.

Align the shiplap joint with the adjoining board and press down to seat it securely. Use a tapping block or mallet for tight alignment if needed.

Continue laying in rows, maintaining the staggered layout.

Fixing

Secure each board using 22mm wood screws or staples. Fix at 200mm centres along all board edges and through the midline for maximum hold.

Ensure fixings are flush with the board surface—do not countersink too deeply, as this may compromise strength.

Finishing

After all boards are laid and fixed, inspect for any movement or gaps. Use acoustic sealant to close small perimeter or transition gaps if required.

Your surface is now ready for final floor finishes—vinyl, carpet, tiles, or wood flooring can be installed directly over GenieBoard 302 without delay.