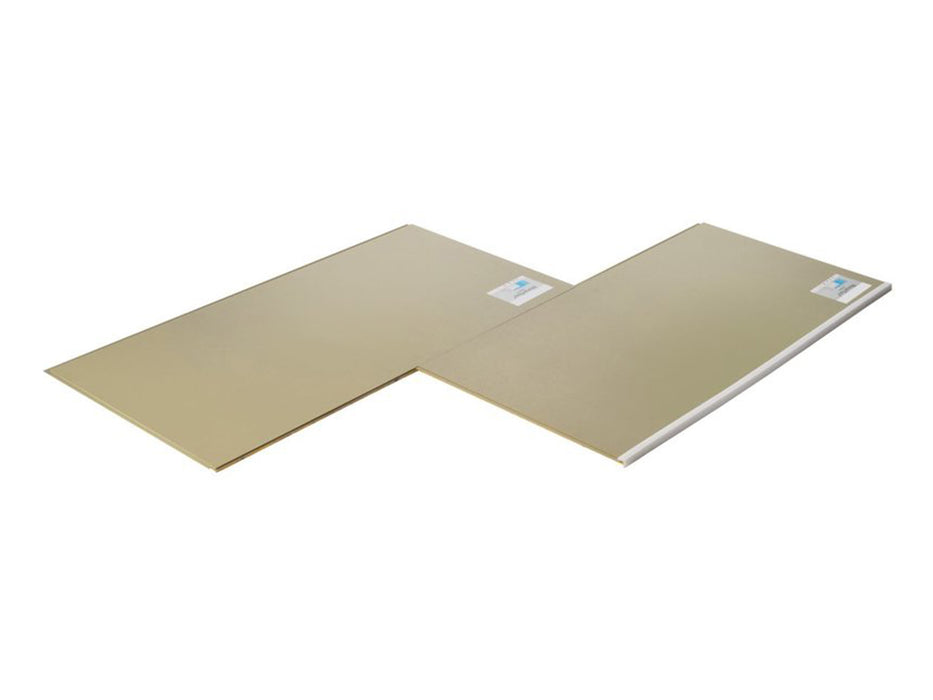

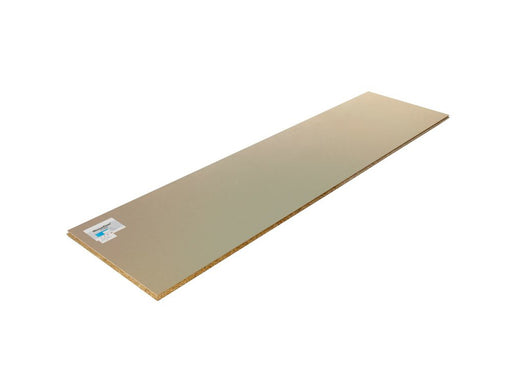

The Monarfloor Deck 9 is a high-performance acoustic deck overlay system designed to reduce sound transmission through both existing timber and new concrete floors. With a minimal floor height increase of just 17mm, it is ideal for projects where maintaining ceiling height or minimising floor build-up is critical. The system is Part E compliant, flame-retardant, and suitable for both refurbishment and new build applications.

What Are Acoustic Floor Boards?

Acoustic floor boards are specialised flooring solutions designed to reduce airborne and impact sound transmission through floors. By incorporating materials like resilient foam and moisture-resistant layers, these boards absorb vibrations and minimise sound transfer, creating quieter environments. They are often used in residential and commercial buildings where soundproofing is a priority.

How Do the Monarfloor Deck 9 Acoustic Floor Boards Work?

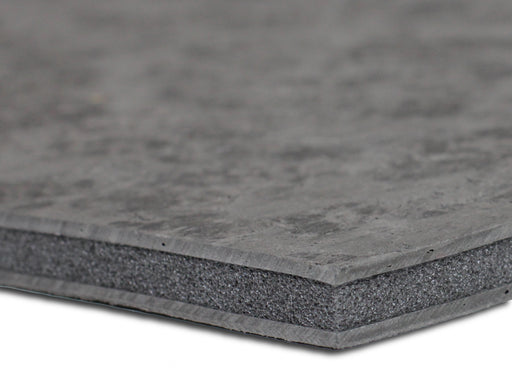

The Monarfloor Deck 9 works by using a composite design:

-

8mm Low Resonance Acoustic Chip (LRAC) foam: Disrupts sound vibrations and reduces resonance.

-

9mm moisture-resistant MDF: Provides a durable and stable surface for flooring finishes.

These materials are bonded with a high-performance water-based adhesive and feature tongue-and-groove edges for easy installation. When installed as a floating floor system, the Deck 9 creates a resilient layer that absorbs impact noise and prevents sound waves from passing through the structure.

How Effective Are the Monarfloor Deck 9 Floor Boards at Stopping Nuisance Noise?

The Monarfloor Deck 9 provides significant soundproofing benefits:

-

Impact Sound Reduction: Superior at minimising vibrations caused by footsteps, furniture movement, and other impact noises.

-

Airborne Sound Reduction: Effective at dampening airborne noise when installed as part of a complete soundproofing system.

-

Complies with Robust Detail standards (E-FC-1; E-FC-2), ensuring excellent acoustic performance in both new build and conversion projects.

Where Can the Monarfloor Deck 9 Boards Be Used?

The Deck 9 boards are versatile and can be used in:

-

Refurbishment projects: Improves the acoustic properties of existing timber or concrete floors.

-

New build developments: Ideal for meeting strict Building Regulation requirements.

-

Floors requiring minimal height increase: Adds only 17mm to the overall floor height.

-

Spaces with mixed flooring types: Works well under hardwood, carpet, or tile finishes.

How to Install the Monarfloor Deck 9 Floor Boards?

- Prepare the Subfloor:

-

Ensure the subfloor (timber, chipboard, OSB, decking ply, or concrete) is clean, level, and dry.

- Lay the Boards:

-

Position the boards as a floating floor system using a broken bond pattern for stability.

-

Align the tongue-and-groove edges and press them together for a tight fit.

- Add Acoustic Sealant:

-

Seal the perimeter of the floor with an acoustic sealant or flanking strips to prevent sound leaks.

- Fix with Adhesive:

-

Apply adhesive to the tongue-and-groove joints for enhanced stability.

- Finalise the Installation:

-

Allow the adhesive to set before applying the final floor covering.

What Are the Benefits of Using the Monarfloor Deck 9 Acoustic Boards?

-

Minimal Floor Height Increase: Adds only 17mm to the total floor height, preserving ceiling space.

-

Superior Impact Sound Reduction: Effectively absorbs vibrations and reduces noise transfer.

-

Part E Compliant: Meets Building Regulation requirements for soundproofing.

-

Robust Detail Certified: Ensures high acoustic performance for both timber and concrete floors.

-

Moisture-Resistant: Durable MDF layer prevents damage from spills or humidity.

-

Quick and Easy Installation: Designed with tongue-and-groove edges for a seamless and straightforward installation.

How to Tile on Top of an Overlay System?

To tile over the Monarfloor Deck 9:

- Prepare the Surface:

-

Ensure the Deck 9 is level and securely installed.

- Overlay with Tile Boards or Ply:

-

Use proprietary tile boards or plywood to add stiffness and improve water resistance. Bond these to the Deck 9.

- Choose Suitable Tiles:

-

Use porcelain tiles for durability and avoid heavy materials like marble.

-

Keep tile sizes under 600mm x 600mm, preferably 450mm x 450mm, for better support.

- Use Appropriate Adhesives:

-

Select adhesives and grouts specifically designed for floating floors. Consult manufacturers for compatibility.

- Follow Manufacturer Instructions:

-

Adhere to the specific guidance provided by the adhesive and grout manufacturers to ensure proper bonding and durability.

We advise you follow the guidance issued by the Tile Association in dealing with floating floors.

By following these steps, you can achieve a stable and durable tiled surface while retaining the excellent acoustic performance of the Monarfloor Deck 9 system.

Here are the main details for this product:

Dimensions: 1200mm x 600mm

Thickness: 17mm

Pack Size: 10 Board Minimum

Weight: 5.1kg per Board

Density: TBC

Coverage: 0.72 sqm

Fire Rating: Flame retardant

Visit our Fitting Instructions section for more detailed guidance specific to your application.

Please contact our team if you have any questions about this product.

Looking for a complete soundproofing solution?

If your looking for soundproofing for a particular situation or application, then the best place to start is with our soundproofing solutions that cover walls, floors, ceilings and reducing echo. Select the relevant application below to find out more.

Wall Solutions

Floor Solutions

Ceiling Solutions

Echo Solutions

Instructions for use

Monarfloor systems are regularly used in regulation E work. When used in conjunction with mineral wool and resilient bars in the ceiling below, Monarfloor systems will exceed the levels required for regulation E.

Monarfloor Deck 9 platform floor / floating floor (FFT5) system on a timber sub-floor with a resilient bar system:

Diagram Key:

1. Acoustic Flanking Band – reduces impact vibration transmission via party and flanking walls and assists in reducing airborne sound paths

2. 100mm 45kg/m³ insulation

3. 22kg/m² double boarded ceiling on resilient bars perpendicular to joist direction

4. Monarfloor Deck 9 system on existing timber floor (subject to condition) or new 18mm chipboard deck on 200 x 50mm timber joists

Installation at a glance

- Flank all perimeter with Monarfloor Flanking Band

- Level the sub-floor to the required tolerance

- Lay Monarfloor Deck 9 platform floor / floating floor (FFT5) system over existing sub-floor in a broken bond pattern, applying Monarfloor Adhesive to all tongue and groove panel joints

- Install skirting and trim off excess Flanking Band

Tools & equipment required

- 1 litre of Monarfloor® Acoustics Adhesive for every 21.5m2 of deck (approx). Note: Adhesive should be applied in well ventilated rooms

- 1 linear metre of Monarfloor Flanking Band for every 1m2 of flooring

- Utility knife and straight edge

- Joinery hand/power tools

- Check sub-floor is suitably prepared

- Ensure the surfaces are structurally sound, clean and dry

- All internal partitions should be installed and built of the sub-floor

- Kitchens and bathrooms should also be built of the sub-floor (see Monarfloor Generic Kitchen & Bathroom Detail Drawings)

- Ensure the correct mineral wool insulation has been packed tightly between the floor joists

Tiling on top of Monarfloor

We advise you follow the guidance issued by the Tile Association in dealing with floating floors, which is:

- Adhesives and grouts must be suitable for floating floors. There are various systems depending on the individual manufacturers detailing.

- Proprietary tile boards or ply, can be overlaid to provide additional water tightness, and or stiffen the floating floor. These must be bonded.

- Tiles should ideally be porcelain. We do not advise thick heavy tiles such as marble etc as they are more susceptible to fracture.

- Tile format must be kept as small as possible (600 x 600mm max). We would advise 450mm x 450mm.

You should also speak to the adhesive manufacturer that is being used as they all have specific detailing to their own products.

Care of materials

Materials must be kept in a dry storage area at all times.

Working Safely

- Working on any building site can be a hazardous activity. Only suitable persons having appropriate competence, training and physical fitness should be allowed onsite.

- Personal Protective Equipment (PPE) must be worn at all times.

Visit our Fitting Instructions section for more detailed instructions relating to your specific application.

Check out our Soundproofing Guides for more information, advice and tips on all aspects of soundproofing.